Products

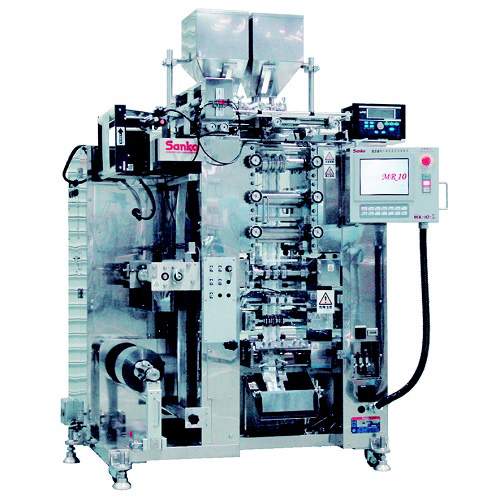

MR11-[]LΣ

High -performance machine of multi-line 4-side searl liquid packaging machine. No air required with standard configuration.

●Suitable for packaging shampoos and cosmetics.

●Since the heater is built into the second horizontal seal roller, stable sealing is performed even for fillings that easily foam, such as oil and vinegar.

●No air required in the standard configuration.

Package shape

Filling

Packaging speed

Bag length

70 to 210mm(2div)

Bag width

Diameter of packaging film

Power source

Machine size dimension

Machine weight

Standard device

Safety unit(Interlocks)It is prohibited to run the packaging machine with the safet... More

Control board: touch panelA touch panel for setting and operating the packaging machin... More

Photocell pattern matching unitControl the film feeding by matching the film mark distance,... More

Film joint detector unitDetects the joint tape of the film and performs the set alar... More

Film End detector unitWhen the film on the packaging shaft ends, an alarm or machi... More

Film shortage warning unitAn alarm will be activated when the remaining film on the pa... More

Remaining film indicator unitThe remaining amount of film on the packaging shaft is calcu... More

Heater abnormal temperature detector unitWhen the temperature of the heat sealer deviates from the se... More

Product counter unitCounts and displays the number of bags packed by the packagi... More

Sealer pressure manual screw control unitAdjust the pressing force of the heat seal roller by turning... More

Heater for second horizontal sealing rollA heater is built into the second horizontal seal roller. More

Air expelling roll unitThe air inside the bag is removed with a squeezing roller wh... More

Sealer unit for 4-side sealThis is the configuration of the sealer for 4-side seal pack... More

Both sides notching unitMake opening notches on the left and right sides of the 4-si... More

Cutter unitCut each bag straight. More

Vertical slitter unitSeparates multi-line bags into individual bags. More

Packaging film braking unitBrake the film to prevent sagging of the film. More

Packaging film pull-out roll(non-slip type)Rollers with high grip force feed the film properly. More

Product carry-out guideA slide that discharges the finished bag. More

Option

Air pressure malfunction detection unitWhen the pressure of compressed air supplied to the equipmen... More

Gap display of sealerThe gap between the heat seal rollers is displayed on the to... More

Sealer unit for pair sealThis is the configuration of the sealer for pair bag packagi... More

Pour spout sealing unit

Vertical sealing pre-heater unitShorten the vertical sealing time by preheating the film jus... More

Perforation unitCut perforations in the set number of bags. More

Vertical perforation unitPerforations are applied between multiple lines of bags. More

Bag pulling unitBy pulling the bag after sealing, it assists the vertical sl... More

Packaging film shaft forward-backward moving device(operated by operation panel)The front and rear position of the packaging material axis c... More

Packaging material UV sterilizing unit(Effective up to 10 m/min)Sterilize the film by irradiating it with ultraviolet light.... More

Packaging film roll guider unitWhen the film meanders, automatic correction is performed to... More

Static electricity eliminator unitBy removing static electricity from the film, it prevents un... More

Packaging material section coverCovering the film path prevents dust and dirt from entering ... More

Packaging material section full coverCovering the entire film path prevents dust and dirt from en... More

Clean booth unitBy placing the fan filter unit on the packaging material sec... More

Cascade pumpIt is a vortex type pump, and the impeller rotates inside th... More

Rotary pumpThis is a pump that pumps liquid into the space of two pairs... More

Mohno pumpA high-precision eccentric screw type pump that can be fille... More

Forward/reverse mohno pumpMohno pump capable of intermittent liquid filling of one bag... More

High-speed intermittent pump(servo-type)Piston pump capable of intermittent liquid filling of one ba... More

Plunger pumpPlunger pump capable of intermittent liquid filling of one b... More

Agitator devicePropeller blades stir the filling in the hopper. It has the ... More

Push screw deviceA large bladed screw pushes the filling downwards in the hop... More

HopperA container for storing fillings. More

Level sensor unitWhen the filling in the hopper is insufficient during the op... More

Constant sorting unitThe bags packed by the packaging machine are distributed to ... More

Preset number shutter unitAfter storing the set number of bags packed by the packaging... More

Product carry-out conveyor – 600 mmThis is a conveyor that transports the bags packed in the pa... More

Auto reject discharger unitWhen a defective product bag is detected, the target bag is ... More

Hot roll printerIt is a printing type printer similar to hot printers, and f... More

Thermal printerA printer that thermally transfers ink from a thermal ribbon... More

Ink jet printerA printer that prints expiration dates and other information... More

Stamping unitA type stamp is attached to the heat sealer, and the expirat... More

Air blow gunAir blow gun for cleaning. More

Film edge cutting unitCut off the edges of the film to shape the bag. More

Control panels(display devices optional)Place a tick mark on each adjustment handle. More

Calendar timerAutomatically turn on the power of the packaging machine on ... More

Warning light unitThe signal tower lights up or an alarm sounds in situations ... More

Raising baseThe packaging machine is raised according to the line height... More

Air compressor deviceSupply compressed air to the packaging machine. More

Air dryer deviceBy separating and discharging the moisture contained in the ... More

Usage

Contact

Please feel free to contact us for any questions or consultations regarding our products and technology.

Contact by phone

Working hours 9:00 - 17:00 [Excluding Saturdays, Sundays and public holidays]